Month: April 2022

Can a Hex Set Screw be used instead of a partially threaded Hex Head Bolt?

April 5, 2022

In applications where the working loads are exerted in line with the length of the bolt (called tensile loads), both a fully threaded and a partially threaded fastener are going to be able to support the same load. If the working forces exceed the strength of the fastener, both of these fasteners will fail in the threads at the same load.

The cross-sectional area (the amount of material that supports the load) is smaller across the thread as compared to across the body (also called the shoulder or unthreaded length). In applications where the bolt is subjected to just tensile loads, having a shoulder on the bolt does not provide a significant benefit.

Applications where there are shearing forces (the working loads are exerted across the bolt) are the ones where the presence of a shoulder will provide increased strength–as long as the shear loading is across the shoulder.

The shear strength of grade 5 and grade 8 hex head bolts is 60% of their minimum ultimate tensile strength. Designers prefer to use a partially threaded hex head bolts in applications that encounter shear loading. The best designs make sure that any shear forces are exerted across the body and not across the threads. The body has a larger cross-sectional area than the threads and therefore the body provides a higher shear strength than the threads. On average, the load required to shear a hex head bolt is about 1.2 to 1.5 times higher across the body than it is across the threads, for coarse threaded hex head bolt in diameters from 1/4” to 1 1/4”.

Note that in applications where shear forces are encountered and the shear loads are exerted across the threads, then the use of a partially threaded hex head bolt provides the same shear strength that a fully threaded hex set screw provides.

In answer to the original question, a partially threaded hex head bolt should be used in applications where shear forces are exerted across the shoulder, and either a hex head bolt or a hex set screw can be used in applications that encounter tensile loads.

Related Posts

What are the Benefits of Coating Fasteners?

What exactly is a coating, and why are coatings important for industrial fasteners? Coating refers to the use of powder or chemical additions to the surface of…

Why is Plating Important for Industrial Fasteners?

What exactly is a plating, and why are platings important for industrial fasteners? Plating refers to the process of “electroplating,” where a metallic finish…

What is a PPAP and how does it compare to other certifications?

Many customers will request a “cert” (certification) when ordering fasteners. The term “cert” can have different meanings from one customer to another.

March Distribution Performance Report

April 5, 2022

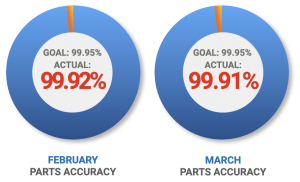

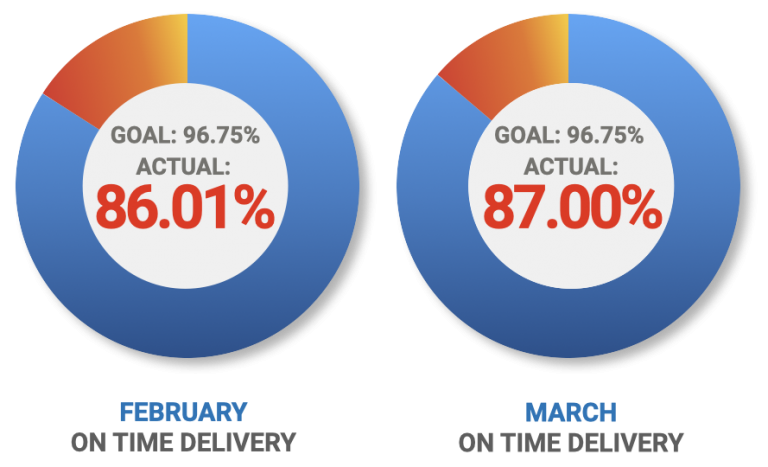

Earnest Machine is pleased to announce that our On Time Delivery improved by 0.99% in March. This is excellent to see as this metric has now experienced three months of continuous improvement. Not only that, but both our Quantity Accuracy and Order Entry Accuracy held steady and experienced no change when comparing performance metrics from February to March. And, even though our Part Accuracy experienced a minor decrease of 0.01%, our team is still excited to see the gains we’ve made within the past month and continues to work harder than ever to create great experiences for our customers.

Additionally, if you would like information regarding supply chain challenges the industry is currently facing, be sure to check our out latest Supply Chain Update to get the latest news on parcel freight rates; the lockdown in Shenzhen, China; fuel price increases; trade lane health; steel prices; and so much more.

Part Accuracy: Our Part Accuracy fell by 0.01% and is coming in at 0.04% below goal.

Individual DC scores:

Austell – 99.83%

Indy – 99.98%

England – 100.00%

EMC – 100.00%

Quantity Accuracy: Our Quantity Accuracy Remained Consistent Between February and March.

Individual DC scores:

Austell – 99.88%

Indy – 99.90%

England – 100.00%

EMC – 100.00%

Order Entry Accuracy: Our Order Entry Accuracy Remained Consistent Between February and March.

On Time Delivery: Our On Time Delivery improved by 0.99% and is coming in at 9.75% below goal.

On Time Delivery – 87.00%

Service Guarantees: Twenty-nine service guarantees were issued in March for a total of $1,450.00

Related Posts

August Distribution Performance Report

August closed with two out of our four performance metrics trending in a positive direction. Our Quantity Accuracy increased by 0.04% and our On-time delivery…

July Distribution Performance Report

July closed with three out of our four Performance Metrics trending in a positive direction. Our Parts Accuracy increased by an additional 0.02% when compared…

June Distribution Performance Report

Earnest Machine experienced an increase in our Parts Accuracy metric in June surpassing our set goal of 99.95%. Our On-Time Delivery also experienced an…

May Distribution Performance Report

Earnest Machine is happy to report that we experienced a 0.03% increase in our Parts Accuracy, which helped push this metric in line with our set goal of…